A commenter recently asked on the Effect of Orientation post whether twistweight is really equal to the difference between spinweight and swingweight. It’s a common approximation based on the perpendicular axis theorem. That theorem is valid for planar (two-dimensional) objects. A tennis racket is nearly planar, but as mass deviates from that plane, twistweight will increase slightly.

To quantify the error, I looked back at the CAD model I had created for the Effect of Orientation post.

Here are the moment of inertia properties from CAD:

- Swingweight: 306.82 kg·cm²

- Spinweight: 320.01 kg·cm²

- Twistweight: 13.58 kg·cm²

The difference between spinweight and swingweight is 320.01 – 306.82 = 13.19 kg·cm². The twistweight is 13.58 kg·cm², so there is an error of -0.39 kg·cm² or -2.9%. As expected, the actual twistweight is higher than approximated. This error will vary based on the accuracy of my CAD model and the geometry of the racket, but it should be somewhat close to that value.

I have a prototype device to measure twistweight more directly (UPDATE: The Twistweight Adapter is available.), as I’ve found a practical issue with determining it from spinweight and swingweight. That issue is a crooked butt cap. When I measure the swingweight of a racket and then flip it 180° and re-measure it, the measured value is often different by tenths of a kg·cm². That’s a small difference in terms of swingweight, but it’s large relative to twistweight determination.

I also have been 3D printing pallets with integrated caps. As seen in the photo, the pallet is two pieces, so the face of the butt end should be nearly perfectly square in the wider direction (affecting swingweight) and perhaps not quite square in the shorter direction (affecting spinweight) if the two halves aren’t perfectly aligned. The door is slightly recessed, so it won’t interfere with measurements.

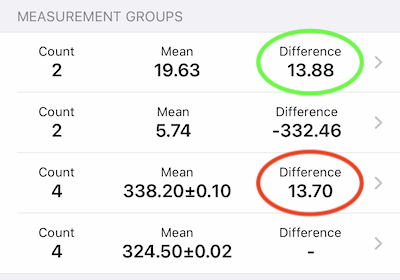

I measured the racket in the photo using both methods on my SW1. In the first (bottom) measurement group, I measured the swingweight of the racket twice in one orientation and twice at 180°. In the second group, I measured spinweight in the same way. As expected, there was a bit of deviation in the spinweight measurement, likely due to misalignment of the pallet halves. The difference of 13.70 kg·cm² is circled in red. Then, I measured my twistweight device empty and finally with the racket. The more directly measured twistweight of 13.88 kg·cm² is circled in green.

In this sample measurement, there was less difference between the two methods than there was in CAD. I haven’t explored why. There is error in all the measurements, and I haven’t used the prototype twistweight device enough to fully understand its capabilities.

So, back to the original question: is twistweight really the difference between spinweight and swingweight? Not exactly, but it’s a pretty good approximation. Practically, as long as the butt cap of the racquet is square, it’s useful, especially when the goal is to match the twistweight of similar rackets.

Thanks for the question, Ryan.